Cliccando sul pulsante "Accetta tutti i cookie": l’utente accetta di memorizzare tutti i cookie sul suo dispositivo.

Cliccando su "Impostazioni cookie": l’utente sceglie le tipologie di cookie che saranno memorizzate nel suo dispositivo.

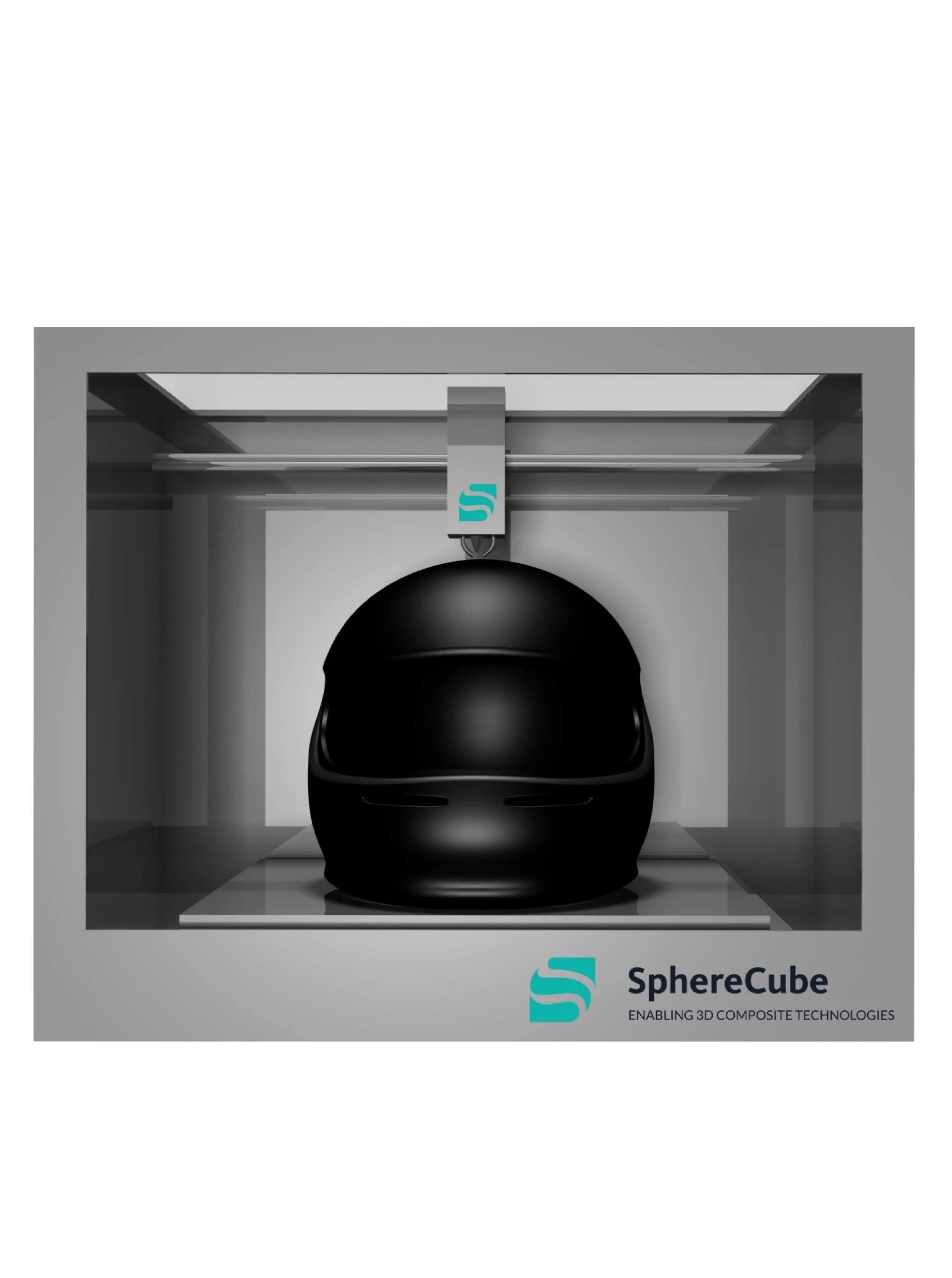

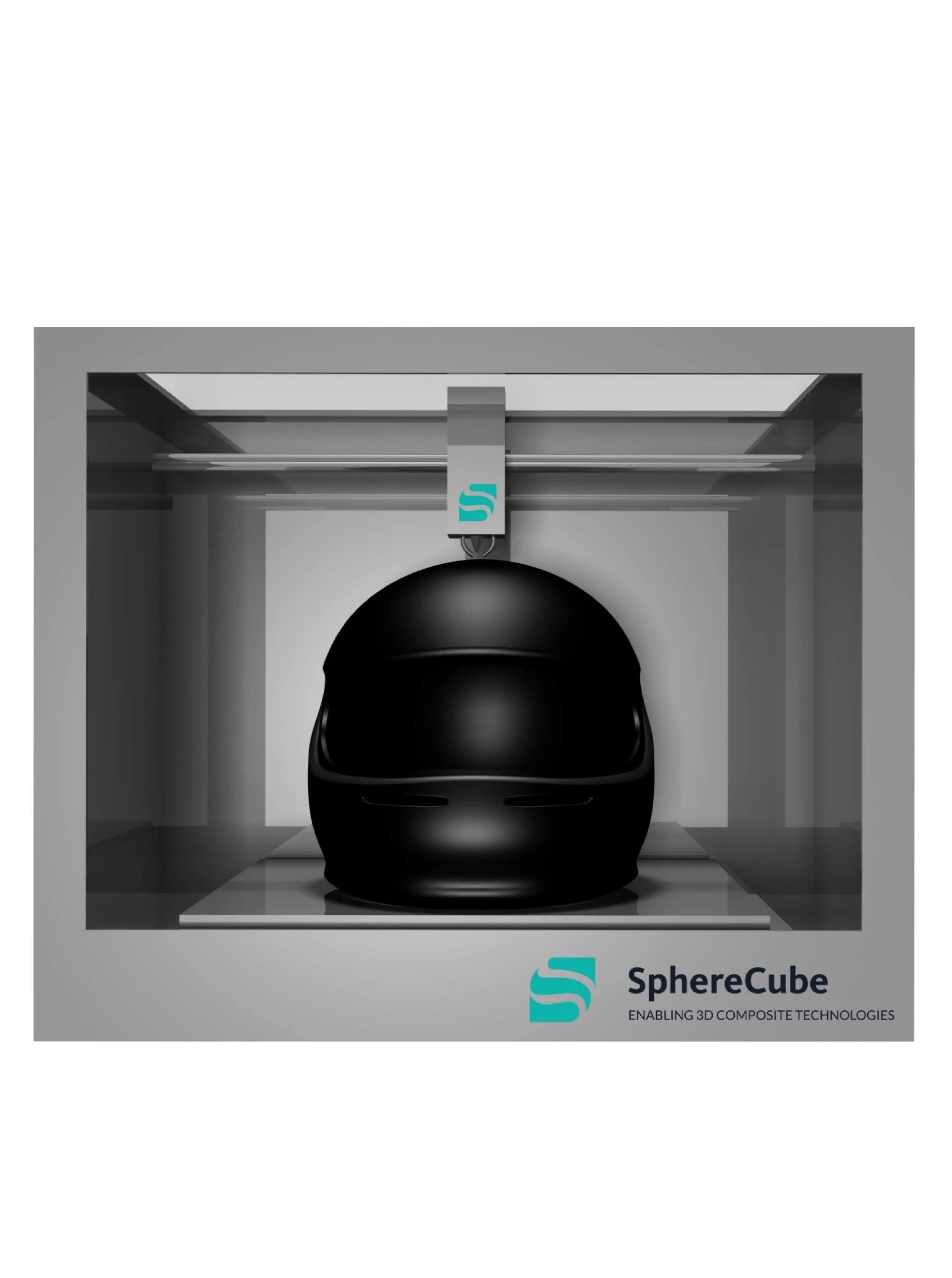

SphereCube 3D printing technology able to process continuously-reinforced high performance composites for next gen mold-less environmentally friendly production.

The high lightness and strength of high-performance composite materials give to your products specific mechanical strengths never experienced with an Additive Manufacturing process.

Fabricate strong components with shapes impossible to achieve with any other system!

The exceptional chemical and physical properties of composite materials guarantee excellent mechanical properties together with a low weight and make them excellent substitutes for metals in applications where high specific performances are required.

Manufacturing parts with composite materials allows to reduce the weight of an object of about three times compared to the same shape fabricated with aluminum. This makes composites a viable alternative to metals for various applications.

Systems that use 3d printing technology allows the fabrication of innovative shapes that cannot be achieved by traditional production process, releasing designers from shape and complexity limitations and opening the doors to new applications.

Fully automated 3D printing process, which guarantees high repeatability, productivity and reduction of production costs of composite materials reinforced with long fibers.

Combining the pros of 3D printing and SphereCube system, the production costs of of composite parts can be reduced, erasing the need of autoclaves and molds.

Fabricate your preferred geometrical shape through new technology with SphereCube and its 3D printing system, freeing yourself from limitations imposed by the use of molds and minimizing process waste.

The strong automation of the SphereCube system and the controls associated with it, ensure high levels of repeatability of the 3D printing process via Thermal Laser Curing.

- 3D printing coupled with the freedom to play with new geometries allow to lower the weight of manufactured parts in applications such as automotive and aerospace, reducing their environmental impact.

Thermal Laser Curing is SphereCube's patented system.

Through the interaction of laser sources with the raw materials involved in the process, this system enables the production of components in composite material with continuous fiber reinforcement and thermosetting matrix.

The innovative production process is able to automatically create products using high-performance composite materials, without geometrical limitations.

Open the doors to 3D printing, one of the key enabling technologies of the Industry 4.0 paradigm.

In the digital factory, the flexibility of Additive Manufacturing enables the production of customized components without increasing the production costs.

The implementation of this technology is essential for business success in the digital factory era.

Choose the Thermal Laser Curing technology to create orthopedic prosthesis with extreme lightness and high resistance at the same time.

SphereCube's ground-breaking production processbenables parts customization according to the anatomical characteristics of the individual patient, at a lower cost than what can be obtained with traditional composites production technologies.

Go towards the extreme lightness of composite materials thanks to SphereCube and get unique components fulfilling the needs of each individual athlete.

With the Thermal Laser Curing system it is possible to identify the ideal solution and customize it in terms of design, weight and anatomical characteristics, maximizing the performance of each individual athlete in a wide range of sport disciplines.

Visualize the future and make it real with Thermal Laser Curing, designing and manufacturing parts that will make aviation history owing to their lightness and distinctiveness.

Combining the flexibility of Additive Manufacturing with the strength of high-performance composite materials, the production of small batches for the aerospace sector has never been easier, faster and cheaper.

Fabricate parts never seen before in the naval sector and take advantage of the extreme flexibility of Additive Manufacturing combined with the specific performance of composite materials.

SphereCube's patented system enables the production of components with shorter delivery times than traditional processes and to have a real-time response to customer needs.

Take advantage of the high mechanical properties of high-performing composite parts and give life to timeless projects.

Customize your ideas exploiting of the enormous versatility of SphereCube's innovative system.

SphereCube begins its adventure with the aim of solving the problems of the composites industry:

2019 - Ranked first in the eCapital Business Plan competition.

2020 - The company takes shape as a spin off of the Marche Polytechnic University (UNIVPM).

The initial idea becomes a business truth thanks to the continuous research, experimentation and innovation process guiding all the revolutionary projects.

Following the first experimentations the scientific confidence in the idea behind the project grows.

And togetehr with it, arises the awareness that 3D printing of thermosetting matrix composites will revolutionize the world of industrial production.

The fabrication of the first tangible shapes proves the true innovation behind the system and allows to push the experimentation on the production process and on the raw materials involved.

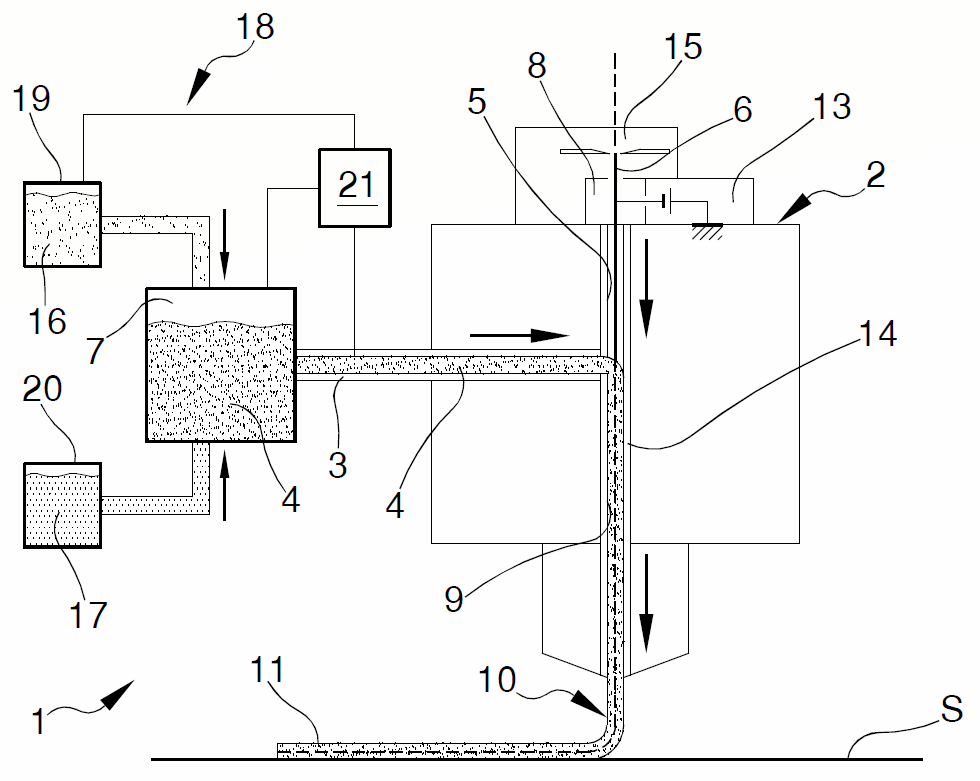

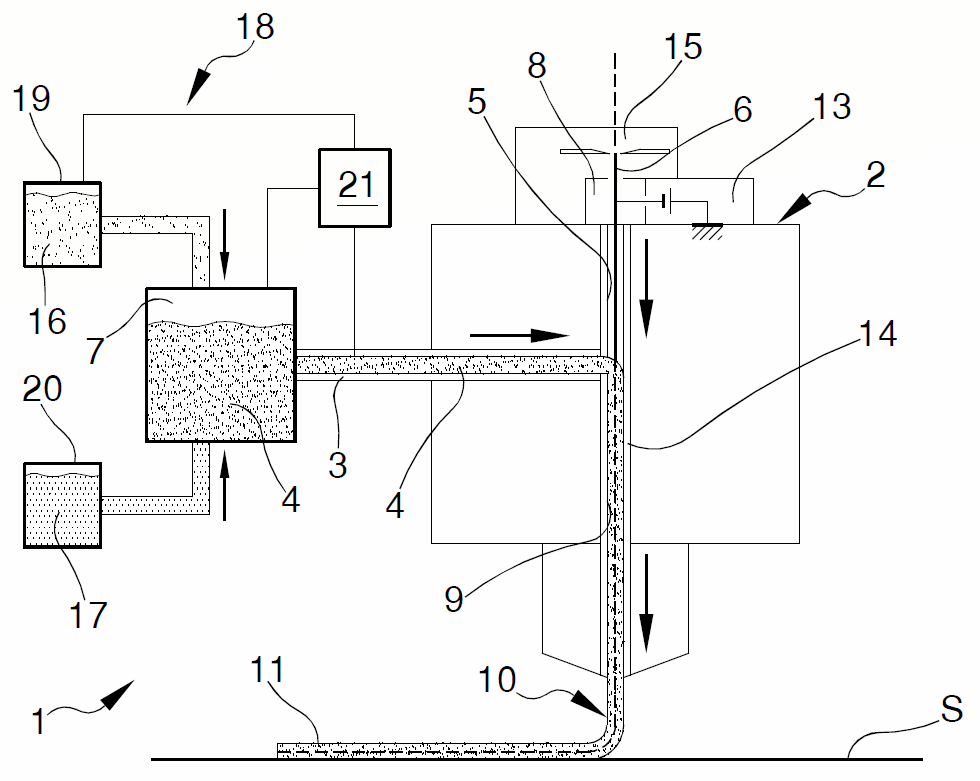

Following the experimental phase and the acuisition of full awareness of a correct functioning system, SphereCube filed its first patent related to the deposition system of high-performance composite materials.

The Thermal Laser Curing technology will revolutionize the world of composite materials industrial production.

The first prototype of the machine is under construction.

... To Be Continued ...

SphereCube begins its adventure with the aim of solving the problems of the composites industry:

2019 - Ranked first in the eCapital Business Plan competition.

2020 - The company takes shape as a spin off of the Marche Polytechnic University (UNIVPM).

The initial idea becomes a business truth thanks to the continuous research, experimentation and innovation process guiding all the revolutionary projects.

Following the first experimentations the scientific confidence in the idea behind the project grows.

And togetehr with it, arises the awareness that 3D printing of thermosetting matrix composites will revolutionize the world of industrial production.

The fabrication of the first tangible shapes proves the true innovation behind the system and allows to push the experimentation on the production process and on the raw materials involved.

Following the experimental phase and the acuisition of full awareness of a correct functioning system, SphereCube filed its first patent related to the deposition system of high-performance composite materials.

The Thermal Laser Curing technology will revolutionize the world of composite materials industrial production.

The first prototype of the machine is under construction.

... To Be Continued ...

PR MARCHE FESR 2021/2027 – ASSE 1 – OS 1.1– AZIONE 1.1.2 – Intervento 1.1.2.1 - Sostegno a progetti di innovazione e diversificazione di prodotto o servizio negli ambiti della strategia regionale per la specializzazione intelligente 2021-2027. CONTRIBUTO PUBBLICO CONCESSO PARI A EURO 15.087,40

VVISO PUBBLICO PER IL FINANZIAMENTO DELLA COSTITUZIONE E/O FUNZIONAMENTO DI START-UP GIOVANILI, NELL’AMBITO DELLA PRIMA EDIZIONE DELL’AVVISO GIOVANI E IMPRESA – CAPOFILA COMUNE DI ANCONA CUP E38D24000020009 - Contributo pari ad 11.460,00

SphereCube was awarded a non-repayable grant by the Marche Region under the funding announcement "L.R. 6 del 29/04/2021 Sviluppo della comunità delle start-up innovative nella regione Marche: Sostegno all'avvio e primo investimento delle start-up innovative".

SphereCube has been selected from over 400 start-ups for an incubation and mentoring programme with the innovation hub ComoNext. The collaboration includes networking and presentations with potential customers and investors.

SphereCube was the winner of the Smart Money tender promoted by Invitalia, receiving non-repayable fundin, for the purchase of services from incubators, accelerators, research organisations and innovation hubs.

SphereCube has been awarded the funding in question, announced by the Municipality of Ancona as part of the POR FESR 2014/2020, by presenting a project for the development of an innovative bindery machine aimed at revitalising the company in the post-pandemic period. The funding obtained is € 5,000.